About Activity

The employment pattern in the manufacturing industry is changing towards more knowledge- and skills- intensive jobs. However, a lack of available personnel, having the requested skills, especially digital skills, have been identified in the manufacturing sector. The Industry 4.0 revolution and the related accelerated technological evolution is creating a dynamic environment regarding the future skills and competencies. Additionally, the manufacturing sector is entering in a new era, where novel life-long learning schemes need to keep up with the rapid advances in production related to 4.0 technologies, tools and techniques.

Novel and innovative knowledge delivery mechanism, utilizing modern technology-enabled (e.g., ICT, high-grade industrial didactic equipment etc.), real-life and life-long learning “environments” for building competence and boosting product and process innovation, have to be employed. The current transformation of research results into new products and processes is inadequate. Modern concepts of training, industrial learning and knowledge transfer schemes can contribute to improving the innovation performance of European manufacturing.

The Teaching Factory Paradigm, developed by Prof. George Chryssolouris and Director of the Laboratory for Manufacturing Systems and Automation (LMS), Dept. of Mechanical Engineering and Aeronautics – University of Patras, is an effective and innovative knowledge delivery mechanism introducing a paradigm shift to the manufacturing education. The Teaching Factory approach aims at an adaptable and much broader use of novel learning methods for the introduction of young engineers to a wide spectrum of manufacturing problems.

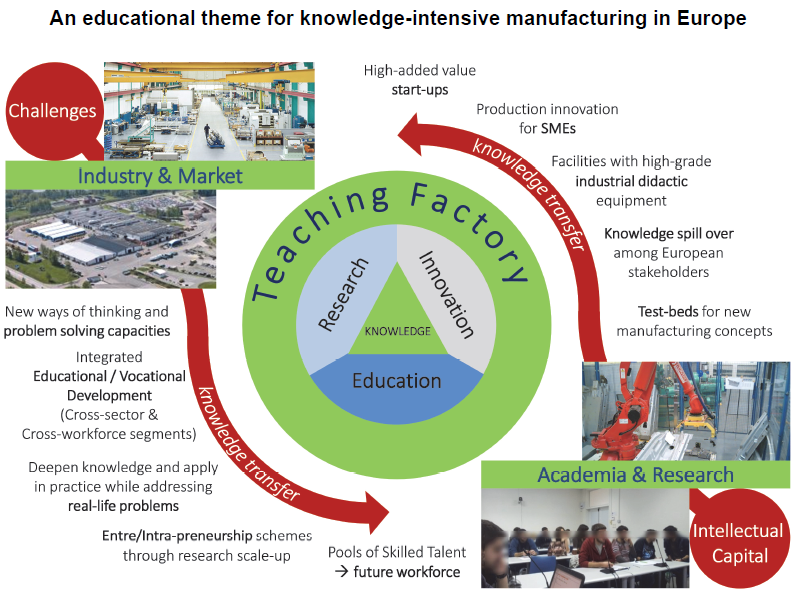

At conceptual level, the Teaching Factory paradigm is based on the knowledge triangle notion. Its aim is to effectively integrate education, research and innovation activities into a single initiative, involving industry and academia. To that effect, the proposed Teaching Factory paradigm focuses on integrating industry and academia, through novel adaptations with the teaching / training curricula, achieved by the deployment of ICT-based delivery mechanisms. The Teaching Factory follows a two-way knowledge transfer channel, where manufacturing topics are the basis for new synergy models between academia and industry.

The “lab-to-factory” operation mode aims to transfer the knowledge from academia to industry. Industrial-grade or didactic equipment installed into the academic facilities can be used as test-beds and demonstrators for new technological concepts to be validated by experts and researchers.

The technology and knowledge can be transmitted back to industry for introducing an engineering or management team to the new concept or solution. This mode can also be used for training and re-training operators on new manufacturing technologies and concepts. There are numerous manufacturing concepts that might be too costly and time consuming to be initially tested on their actual production. The Teaching Factory can be therefore a useful facility for the validation of such concepts, while bridging the gap between innovation and education.

In the “lab-to-factory” operation mode, interactive training sessions aim at knowledge transfer from academic to and industrial environment, e.g., advances in flexible robotic cells and the way they could be applied to real-life problems of a company producing automation and control equipment. Delivery mechanisms comprise live videos and audio interactions, real-time presentations and demonstrators, through advanced ICT configurations.